- Home

- --- Training Center

- --- Testing

Testing

I. FOR WORKING ABROAD:

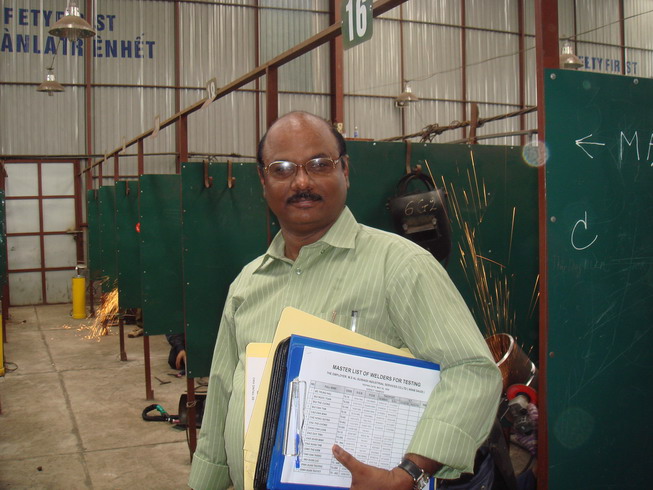

Employer will test directly skills of workers in our workshop or other assigned testing sites (if any) so they can choose their idea candidates.

All candidates are educated well and provided protective equipment and clothes.

Your benefits of Our Qualification for Welders at a Glance

With our qualification of welders and welding procedures you can:

All students are trained by well skilled and experienced teachers.

Throughout studying process, teachers can test students suddenly or after the course to be sure ability of students according to these criteria:

1.1 Butt Welds

1.1.1 No cracks are permitted

1.1.2 As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free from overlaps, abrupt ridges, and valleys.

1.1.3 The thickness of reinforcement shall not exceed 3 /16 in.

1.1.4 Undercuts shall not exceed 1 /32 in. or 12½ % of the wall thickness whichever is less.

1.1.5 For single-welded joints (i.e. butt joints welded from one side), concavity of the root surface shall not reduce the total thickness of the joint, including reinforcement, to less than the nominal thickness of the thinner component being joined

1.1.6 For single welded joints, the excess root penetration shall be exceed the lesser of 1 /8 in. or 5 % of the inside diameter of the pipe.

1.1.7 The total joint penetration shall not be less than the thickness of the thinner component being joined, except that incomplete root penetration is acceptable if it does not exceed the lesser of 1 /32 in. or 20 % of the required thickness, and its extent is not more than 1 ½ in. in any 6 in. length of weld.

1.1.8 Concavity of the root surface shall not be reduced the total thickness of the joint, including reinforcement, to less than the thickness of the thinner of the components being joined.

1.1.9 The length of unfused bead or layer areas shall not be more than 20 % of the circumference of the pipe, or of the total length of the weld, and no more than 1½ inches in any 6 in. length of weld. 1.2 Seal, Socket, and Fillet Welds

1.2.1 As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free overlaps, abrupt ridges, and valleys.

1.2.2 Limitation on imperfections in socket, fillet and seal welds are the same as in Paragraph 1.1.4 and 1.19 for cracks, lack of fusion, and undercut.

1.2.3 Socket and fillet welds may vary from convex to concave.

Employer will test directly skills of workers in our workshop or other assigned testing sites (if any) so they can choose their idea candidates.

All candidates are educated well and provided protective equipment and clothes.

Your benefits of Our Qualification for Welders at a Glance

With our qualification of welders and welding procedures you can:

• Be sure you employ welders whose skills are verified and can follow the instructions in a given welding procedure specification.

• Be confident that your welding procedure specification will produce a welded component with properties that satisfy the design requirements.

• Ensure the quality of welded components.

• Rely on our qualified experts with extensive experience in welder testing and welding procedure qualification.

• Comply with applicable codes and standards.

• Benefit from our fast inspection and testing times.

• Reduce the risk of company liability with documented safety standards.

II. FOR GETTING CETIFICATE:• Be confident that your welding procedure specification will produce a welded component with properties that satisfy the design requirements.

• Ensure the quality of welded components.

• Rely on our qualified experts with extensive experience in welder testing and welding procedure qualification.

• Comply with applicable codes and standards.

• Benefit from our fast inspection and testing times.

• Reduce the risk of company liability with documented safety standards.

All students are trained by well skilled and experienced teachers.

Throughout studying process, teachers can test students suddenly or after the course to be sure ability of students according to these criteria:

1.1 Butt Welds

1.1.1 No cracks are permitted

1.1.2 As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free from overlaps, abrupt ridges, and valleys.

1.1.3 The thickness of reinforcement shall not exceed 3 /16 in.

1.1.4 Undercuts shall not exceed 1 /32 in. or 12½ % of the wall thickness whichever is less.

1.1.5 For single-welded joints (i.e. butt joints welded from one side), concavity of the root surface shall not reduce the total thickness of the joint, including reinforcement, to less than the nominal thickness of the thinner component being joined

1.1.6 For single welded joints, the excess root penetration shall be exceed the lesser of 1 /8 in. or 5 % of the inside diameter of the pipe.

1.1.7 The total joint penetration shall not be less than the thickness of the thinner component being joined, except that incomplete root penetration is acceptable if it does not exceed the lesser of 1 /32 in. or 20 % of the required thickness, and its extent is not more than 1 ½ in. in any 6 in. length of weld.

1.1.8 Concavity of the root surface shall not be reduced the total thickness of the joint, including reinforcement, to less than the thickness of the thinner of the components being joined.

1.1.9 The length of unfused bead or layer areas shall not be more than 20 % of the circumference of the pipe, or of the total length of the weld, and no more than 1½ inches in any 6 in. length of weld. 1.2 Seal, Socket, and Fillet Welds

1.2.1 As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free overlaps, abrupt ridges, and valleys.

1.2.2 Limitation on imperfections in socket, fillet and seal welds are the same as in Paragraph 1.1.4 and 1.19 for cracks, lack of fusion, and undercut.

1.2.3 Socket and fillet welds may vary from convex to concave.

Copyright by Vietnam Welder - Vietnam Manpower

Address: Thuong Phuc Village, Bac Hong Commune, Dong Anh District, Hanoi, Vietnam

Tel: (+84) 24-3958.4656 Fax: (+84) 24-3958.4436

Email: vietnamwelder@hotmail.com Website: http://vietnamwelder.vn

Tel: (+84) 24-3958.4656 Fax: (+84) 24-3958.4436

Email: vietnamwelder@hotmail.com Website: http://vietnamwelder.vn

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)